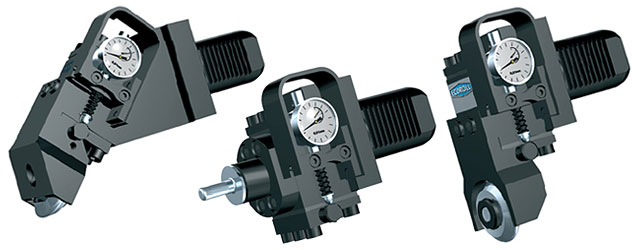

EG5-08F, EGI5, EG5-40M Tools for contours, concave fillets, groove bed machining and short bores

from 8.5 mm diameter

Characteristics

- Can be used on CNC or conventional lathes

- Machining in a chuck

- Attainable surface finish Rz < 1 micron (Ra = 0.2 micron)

- Processing of all metallic materials with a tensile strength of 1400 N/mm2 and a maximum hardness of HRC ≤ 45

- Universally useable modular system

- Can be used as right or left-handed tool

- Both directions of rotation possible

Advantages

- Short primary processing time

- Elimination of set-up times and downtimes

- No occurrence of dust and slurry

- Only nominal lubrication required (oil or emulsion)

- Roller head guidance without play and low-friction

- Consistent and controlled machining results through measurement of roller pressure

- Face of the roller free, thus enabling machining close to shoulders and other edges

- Simple replacement of wear parts

EG5-08F and EG5-11F

- Machining of plane or peripheral sides of groove

- Max. rolling depth 20 mm for bores from 8.5 mm diameter (EG5-08F)

- Max. rolling depth 30 mm for bores from 11.5 mm diameter (EG5-11F)

- Spring pack arranged parallel to surface of work piece

- Cantilever-mounted roller

EGI5-32

- Machining of bores from 32 mm

- Max. rolling length: 80 mm

- Spring pack arranged parallel to surface of work piece

EGI5

- Machining of bores from 55 mm diameter

- Max. rolling length: 140 mm

- Spring pack arranged to surface of work piece at less than 45°

- Two replacement rollers are included in scope of supply

EG5-40M

- Machining of external surfaces with contours

- Suitable for low and medium strength materials

- Spring pack arranged parallel to surface of work piece

- Extremely narrow roller with integral 4-point bearing

EG5-40M-45°

- Machining cylinders with subsequent radius to the plane surface

- Suitable for low and medium strength materials

- Spring pack of base component arranged to surface of work piece at less than 45°

- Extremely narrow roller with one integral 4-point bearing

Introduction | EG5 | EG14 | EG45 | EG5-08, EG15, EG5-40M | Back to product selection |