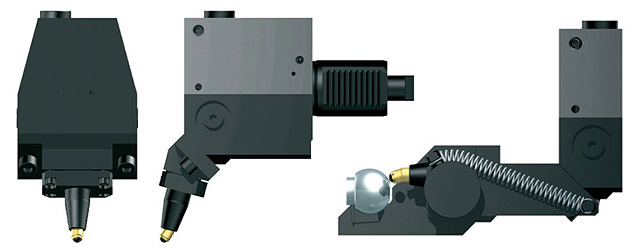

Hydrostatic tools HGx-5 and HGx-6 for rotation symmetric surfaces and complex contours

for rotation symmetric surfaces and complex contours

HGx-5

- Use on CNC lathes with live tooling recommended

- Integral high-pressure pump; no feed line required

- Immediately ready for operation after locating in the revolver

- With VDI shanks in diameter range 20 - 80 mm for all popular drive systems

- Symmetric tool construction and double geared VDI shank enable use as right or left-handed tool

HGx-6

- Similar to the HGx-5 model but with pivoting rolling element for ball heads and domes

- Integral high-pressure pump; no feed line required

- HG13-6R for roller burnishing concave fillets

Integral high-pressure pump

- Standard for HGx-5, HGx-6 and HGx-7

- For use on CNC lathes with live tooling and tooling and tool connection to DIN 69880 (VDI shank) with diameters of 20 - 80 mm

- Low pressure emulsion feed via the revolver

- Actuation of high-pressure pump by tool drive

- Any direction of rotation

- max. speed 3000 rpm

- Adjustable pressure-relief valve

- Connection for manometer for adjusting rolling pressure available

- Machine side emulsion filter = 40 micron required

Introduction | HGx1, HGx2, HGx4, HGx11 | HGx5 and HGx6 | HGx7, HGx20, HGx23, HGx29 |

HGx9, HGx10, HGx19 | mit FR-Rolle | Accessories DD | Accessories HGP | Back to product selection |