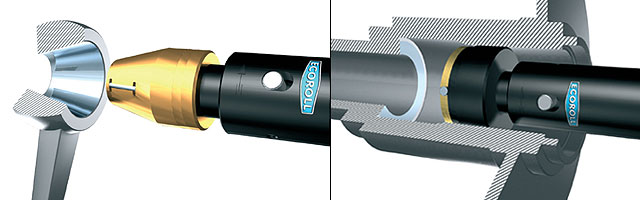

RP, RDP, RK, RKA tools for non-cylindrical surfaces, plane surfaces and cones (internal and external)

Characteristics

- Applied force of tool in axial direction

- Can be used in almost all machine tools

- Either the tool or the work piece rotates depending on the type of machine

- Processing of all metallic materials with a tensile strength of 1400 N/mm2 and a maximum hardness of HRC ≤ 45

Advantages

- Reliable function; high precision

- Large range of contours and combinations of diameters available

- Economical due to extremely short primary processing time

- Consistent machining results through optimum spring characteristics

- Tool shanks available for all clamping systems

- Simple replacement of wear parts

Configuration

- Tools are usually equipped with Morse taper, but can be fitted with cylindrical shanks to DIN 69880 (VDI shank) or shanks for other clamping systems.

- Lamination of the springs is optimally designed for each individual machining task.

- The roller head is specially matched to the dimensions of the work piece and purpose built.

Introduction | G | R | RA | RD and RAD | RP and RK | Back to product selection |